Powder Mill

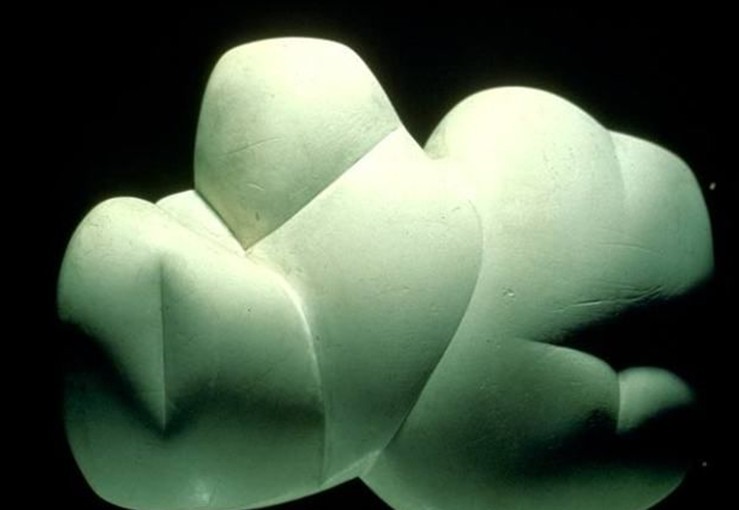

The industrial use of sepiolite and sepiolite powder mill

There are five types of Shanghai CLIRIK HGM series Sepiolite powder grinder, powder mill equipment, they are HGM80, HGM90, HGM100, HGM100A and HGM125. Sepiolite powder grinder, powder mill equipment, the granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.0057mm), and the capacity (ton/hour) ranges from 0.4T/H to 12T/H.

Sepiolite after processing by Sepiolite powder grinder, powder mill equipment can be used in many areas. According to the statistics, sepiolite uses are up to more than 130, it has become one of the world's most widely used mineral raw materials.

Features and advantages of Sepiolite powder grinder, powder mill equipment:

● High Efficiency

Under the same finished final size and the same motor power, the capacity of Sepiolite powder grinder, powder mill equipment is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

● Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

● High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

● High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

●Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

●Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.

CLIRIK Sepiolite powder grinder, powder mill equipment, which is designed by our engineers and technicians on the basis of multiple innovation, test and experience over two decades, has absorbed many advantages of home and abroad mill manufacturing technique. It has been proved by thousands of customers that our machine has outstanding features and stable quality. CLIRIK Sepiolite powder grinder, powder mill equipment can upgrade its production and the additional value which is suitable for our customer to use. It is the ideal equipment for fine milling.

Inquiry:

Product List