Crusher

Cone Crusher

Application range: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, etc.

Materials: sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc.

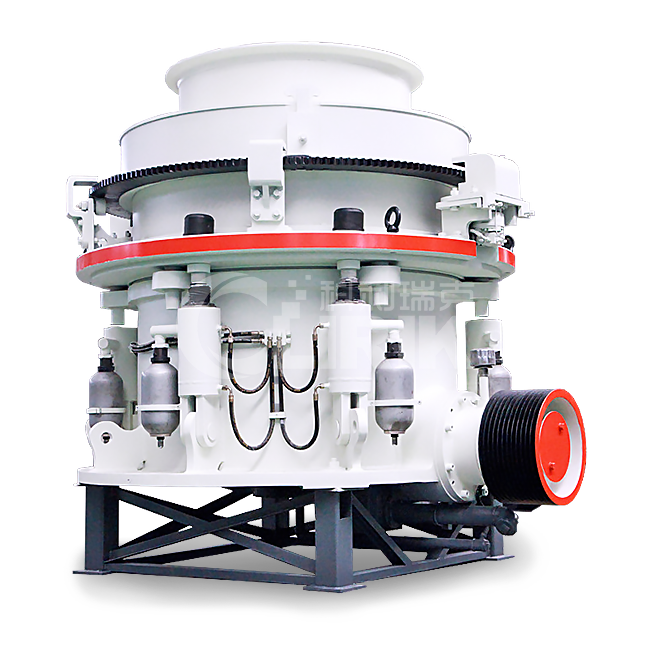

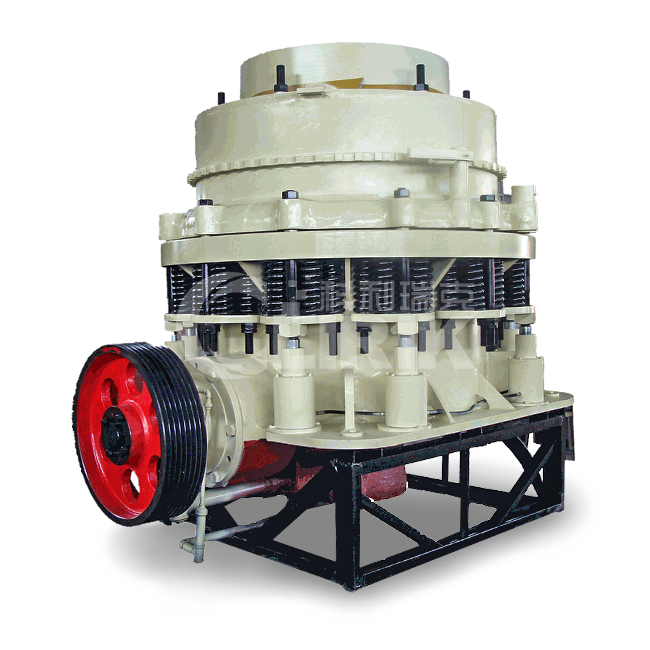

Cone Crusher Images

Cone Crusher Features

Cone crushers are mainly used in the second and third stages of crushing in metal mines and construction sand and gravel processing.

Because of their strong crushing capacity and large output, the sand and gravel production lines using hydraulic cone crushers are more used for river pebbles. For the crushing of medium-hard materials.

In addition, the hydraulic cone crusher has a large iron size, and the processed finished sand has a high content of grain products below 8mm.

It has a great comparative advantage in actual use.

The entire production line runs stably, has a good particle shape, and is fully in line with high quality.

The production requirements of machine-made sandstone for construction have enjoyed high praise among customers.

Performance Advantage of Cone Crusher

1. High efficiency. The optimized structure of the fixed main shaft and the small spherical shaft is adopted, which is 5%-15% higher than the efficiency of the old spring cone crusher.

2. High output, the perfect combination design of crushing stroke, crushing speed, and crushing cavity shape is higher than the output of the old spring cone crusher.

3. High quality, using the unique lamination crushing principle to produce the crushing effect between the particles, the needle-like stones are reduced, and the particle size is more uniform.

Main Structure Of Cone Crusher

Cone crusher is mainly composed of the base assembly, eccentric sleeve assembly, transmission assembly, motor assembly, moving cone assembly, fixed cone assembly, etc. The auxiliary part consists of the electrical system, lubrication system, etc.

Application Environment Of Cone Crusher

1. The new cone crusher is safer and more stable in operation, convenient for maintenance, short downtime, guaranteed output, and more suitable for large-scale sand and gravel production systems.

2. The cone crusher adopts a multi-point split hydraulic lubrication control system, which has stronger bearing lubrication and overload protection capabilities, which greatly improves the automation of the entire production line.

3. The cone crusher has re-experimented the design of cavity and stroke, which is more suitable for crushing hard materials such as river pebble, basalt, iron ore, etc. The output is 35%-60% higher than that of an ordinary spring cone crusher.

Working Principle Of Cone Crusher

The cone breaker moves the cone under the action of the eccentric sleeve to make a swing motion, which drives the broken wall to squeeze and grind the material between the wall and the rolling mortar wall. According to the lamination theory, the material is subjected to forces in multiple directions, according to its own texture. After being crushed and polished, stable stone particles are finally formed, which fall from the swing gap of the crushing wall that meets the discharge requirements, and the rest of the materials continue to be crushed until the final requirements are reached.

Technical Parameter

| Model | Moving cone diameter (mm) | Cavity | Feed Size | Discharge Size (mm) | Processing Capacity | Spindle Speed | Power (kw) | Weight | Dimensions (mm) | |

| Gate size (mm) | Opening size (mm) | |||||||||

| CS75B | 900(3') | Fine S | 83 | 102 | 9-22 | 45-91 | 580 | 75 | 15 | 2821*1880*2164 |

| Coarse L | 83 | 102 | 9-22 | 45-91 | ||||||

| CS110B | 1200(4') | Fine S | 127 | 131 | 9-31 | 63-188 | 485 | 110 | 20 | 2821*1974*2651 |

| Medium L | 156 | 156 | 13-38 | 100-200 | ||||||

| Coarse L | 178 | 191 | 19-51 | 141-308 | ||||||

| CS160B | 1295(4') | Thin | 109 | 137 | 13-31 | 109-181 | 485 | 185 | 27 | 2800*2432*2668 |

| Medium | 188 | 210 | 16-38 | 132-253 | ||||||

| Rough | 216 | 241 | 19-51 | 172-339 | ||||||

| CS240B | 1650(5') | Thin | 188 | 209 | 16-38 | 181-327 | 485 | 240 | 55 | 2911*2870*3771 |

| Medium | 213 | 241 | 22-51 | 181-327 | ||||||

| Rough | 241 | 268 | 25-64 | 299-635 | ||||||

| CS315B | 2134(7') | Thin | 253 | 278 | 19-38 | 381-726 | 435 | 310 | 110 | 3613*3251*4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | ||||||

| Rough | 334 | 369 | 31-64 | 798-1270 | ||||||

Inquiry: