Powder Mill

CLUM Ultrafine Powder Vertical Roller Grinding Mill

CLUM Series Ultrafine Powder Vertical Roller Grinding Mill is used for the processing of ultra-fine powder of non-metallic minerals. For example, calcite, marble, limestone, barite, talc, kaolin, wollastonite, gypsum, feldspar, etc.

CLUM Ultrafine Powder Vertical Roller Grinding Mill

CLUM Series Ultrafine Vertical Roller Mill plant can be widely used in such industries as non-metallic mining, chemical and metallurgy. In particular, it is outstanding in the pulverization of white untra-metallic ore. It is capable of providing high quality fillers and additives used in the segments of plastic, rubber, paper-making, PVC, printing ink, coating and pigment industry.

Five Characteristics of CLUM Series Ultrafine Powder Vertical Roller Grinding Mill

1.High quality

High content of fine powder, Narrow size e ditribution, stble quality

2.Full intelligence

Siemens auto telecontrol

3.HIgh yield

5~50% higher than similar plant in the market

4.Durable life cycle

20 years of life cycle

5.Lower cost

50% lower for maintenance cost, 15% lower for finished products cost

Advantages of CLUM Series Ultrafine Powder Vertical Roller Grinding Mill

- Main unit: Reliable and firm design for main unit base avoid broken risk of main unit foundation bolts, which ensure long life cycle of the mill plant.

- Main unit reducer: Adopt very firm three-stage drive reducer, multiple protection for the system, to ensure long life of the reducer.

- All castings of the main unit: casting from top-brand suppliers, excellent quality and durable.

- Rollers and grinding plate: Adopt high anti-wearing alloy materials for rollers and grinding plate. The lifetime is able to achieve 500,000 tons finished products. The whiteness is almost non influence.

- The rollers adopt multiple protective design, to avoid of direct contact between grinding rollers and grinding plate.

- Optimize ultrafine vertical mill system design which ensure high yield and low power consumption.

- Germany SEW or NORD brand reducer motors makes the system excellent functions.

- Optimized design of the classifier impeller, and adopt imported anti-resistance plate, which makes classifiers run in the ways of high efficiency and long lifetime.

- The control system adopts the advanced Siemens WINCC control system.

- The main unit, blower, classifier adopt variable frequency control system, saving energy and low power consumption.

- Accurate system by belt feeding weighing ensure high yield and excellent quality of end products.

Working principle of CLUM superfine vertical mill

The grinding plate is rotated by the main motor via the reducer. Meanwhile, air enters the mill interior via the air inlet. The screw conveyor is responsible for conveying materials. Materials then fall into the center of the grinding plate in rotation. Due to the centrifugal force, the materials evenly move from the center of the grinding plate towards its fringe. While passing across the track in the grinding plate, large blocks of materials are crushed and ground directly by the grinding roller. The fine particles form on the material bed, owing to squeezing, where the inter-particle crushing takes place.

The crushed materials continue to move towards the fringe of the grinding plate until they are taken away by strong air flow at the air ring. Coarse materials will fall on the plate and be ground again.

While the materials along with the air flow pass through the separator located above the grinding plate, the coarse particles return to the grinding plate for re-grind due to the action of the rotor blade; the fine particles along with the air flow will be taken away, collected and discharged as finished product by the powder collector.

Under the centrifugal force, few big particles were thrown out the grinding plate, and fall into the lower grinding chamber, and then is scraped into the slag outlet to be discharged by the scraping plate installed at the bottom of grinding plate.

Rotation speed of classifier impeller is easy to adjust to achieve different size of qualified powder products.

Working principle of CLUM superfine vertical mill

Construction of CLUM Series Ultrafine Powder Vertical Roller Grinding Mill

CLUM Series Ultrafine Vertical Roller Mill mainly consists of the motor, reducer,grinding rollers, grinding plate, pressure-applying device, classifier, mill body, oil station and electric control system.

Grinding roller: main component used for crushing and grinding materials. Together with the liner plate on the grinding plate, it can provide an effective grinding area.

Grinding plate: Component fixed on the output shaft of the reducer and where the grinding rollers grind materials.

Pressure-applying device: Component used for applying sufficient pressure to the grinding rollers to grind materials.

Classifier: A highly efficient and energy saving powder separation device which has the function of separate qualified finished powders and coarse powders.

Main Powder Production Process of the System

The system process include raw material washing, primary crushing, iron separation, secondary crushing, raw materials storage, weighing, iron removing, medicine filling, ultrafine powders grinding, main unit classifying, pipe conveying, pulse bag filter powders collection, finished powders transporation, packaging, compressed air transporation system, power remote control system and PLC central control system etc.

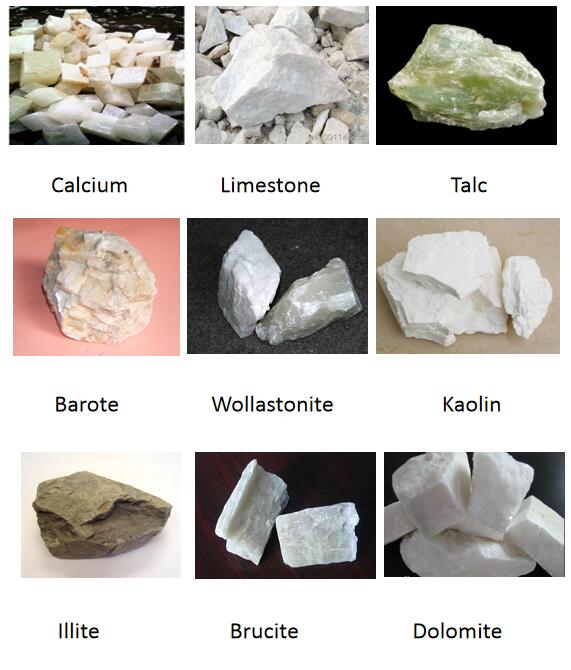

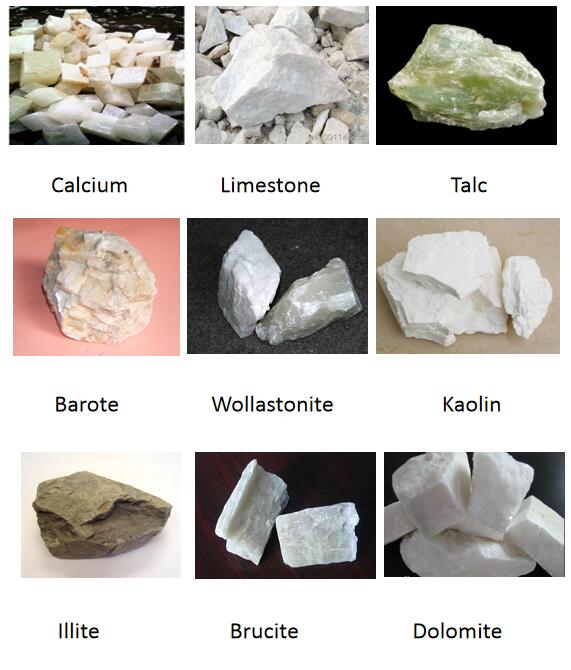

Processing Materials of CLUM Series Ultrafine Vertical Roller Mill

CLUM Series Ultrafine Vertical Roller Mill is a kind of equipment for processing ultra - fine powder and superfine powder, it is mainly used in medium and low hardness, hardness is lower than 6, non-flammable and non-explosive materials. It is widely used in calcium carbonate, marble, limestone, talc, barite, brucite, wollastonite, pyrophyllite, dolomite, kaolin, lime etc.

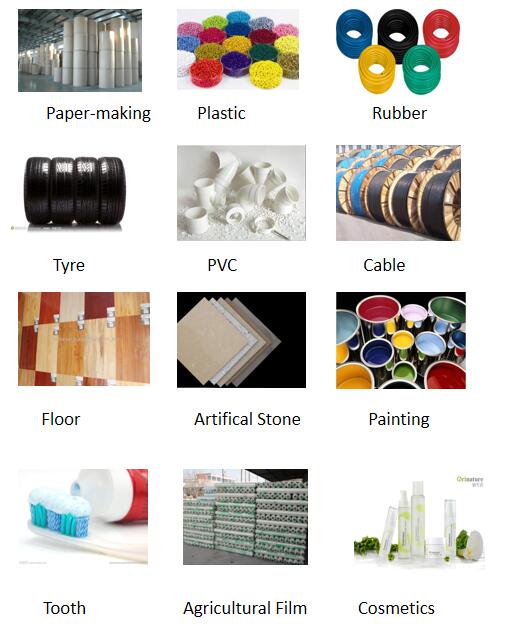

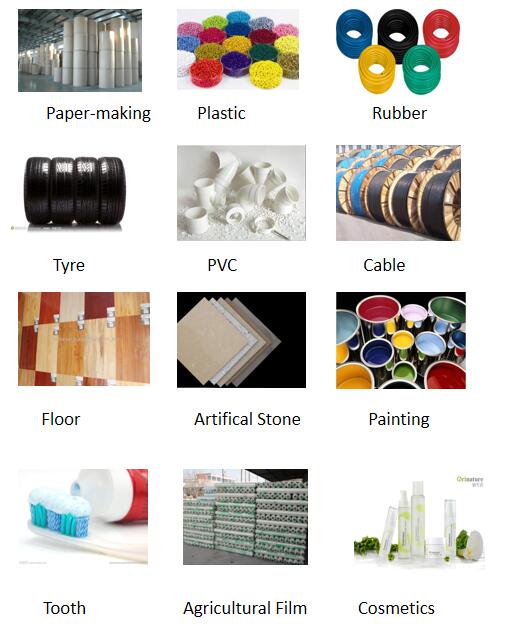

Application of CLUM Series Ultrafine Powder Vertical Roller Grinding Mill

Applications of CLUM ultra fine powder vertical roller grinding mill

Main configuration of CLUM Series Ultrafine Vertical Roller Mill

| MODEL | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Main Unit Power (KW) | 185~250 | 280~315 | 355~410 |

| Roller Qty (PCS) | 3 | 3 | 3 |

| Impeller Qty (PCS) * Power (KW) | 1*30KW | 1*37KW | 1*37KW |

| Multi-head Impeller Qty (PCS) * Power (KW) | 5*15KW | 7*15KW | 7*(15-18.5KW) |

|

Blower Power (KW) |

160~200 | 220~250 | 255~355 |

Main Technical data of CLUM1425Ultrafine Vertical Roller Mill

| Items | Ultrafine GCC (CaCo3) Powders | |||||

|---|---|---|---|---|---|---|

| Capacity | T/H | 11.0-14.0 | 8.0-10.0 | 7.0-9.0 | 5.0-7.0 | 3.0-4.5 |

| Specific Surface Area | cm2/g | 11000±500 | 13500±500 | 15000±500 | 17000±500 | 19000±1000 |

| 325 mesh Residual | % | 0.01 | 0.005 | 0.05 | 0 | 0 |

| Content <2um | % | 34 | 38 | 46 | 54 | 60 |

| Average Particle size: D50 | μm | 4.2 | 3.0 | 2.4 | 1.7 | 1.4 |

| Size Distribution :D97 | μm | 28 | 23 | 19 | 14 | 9 |

| Particle Size Cut Point | μm | 60 | 42 | 36 | 28 | 18 |

| Mositure | % | 0.3 below | 0.3 below | 0.3 below | 0.3 below | 0.3 below |

| Power Consumption | KW/Ton | 37-39 | 38-48 | 45-51 | 50-55 | 110-125 |

| Testing Method |

1. Size distribution: To be tested by Malvern3000 Laser Analyser from MALVERN UK company. 2. Specific surface area: Transffered by average particle size, the unit is related area of 1g powder. 3. Average particle size: To be calculated according to particle size distribution. 4. 325 mesh residual: To be marked by percentage, by putting 1000g wet powder samples through 325 mesh sieve. 5. Mositure: Put 5g sample on moisture analyzer, in 6 minutes with temperature 150℃ 6. Application materials: limestone, calcium carbonate, dolomite, talc barite, wollastonite, brucite, calcium hydroxide, gypsum, coking coal, slag, phosphate and other minerals. |

|||||

Main Technical data of CLUM1632 Ultrafine Vertical Roller Mill

| Items | Ultrafine GCC (CaCo3) Powders | ||||

|---|---|---|---|---|---|

| Capacity | T/H | 13.0-17.0 | 11-13 | 9.0-10.0 | 7.0-8.0 |

| Specific Surface Area | cm2/g | 11000±500 | 13500±500 | 15000±500 | 17000±500 |

| 325 mesh Residual | % | 0.01 | 0.005 | 0.05 | 0 |

| Content <2um | % | 34 | 38 | 46 | 54 |

| Average Particle size: D50 | μm | 4.2 | 3.0 | 2.4 | 1.7 |

| Size Distribution :D97 | μm | 28 | 23 | 19 | 14 |

| Particle Size Cut Point | μm | 60 | 42 | 36 | 28 |

| Mositure | % | below 0.3 | below 0.3 | below 0.3 | below 0.3 |

| Power Consumption | KW/Ton | 37~39 | 38~48 | 45~51 | 50~55 |

| Testing Method |

1. Size distribution: To be tested by Malvern3000 Laser Analyser from MALVERN UK company. 2. Specific surface area: Transffered by average particle size, the unit is related area of 1g powder. 3. Average particle size: To be calculated according to particle size distribution. 4. 325 mesh residual: To be marked by percentage, by putting 1000g wet powder samples through 325 mesh sieve. 5. Mositure: Put 5g sample on moisture analyzer, in 6 minutes with temperature 150℃ 6. Application materials: limestone, calcium carbonate, dolomite, talc barite, wollastonite, brucite, calcium hydroxide, gypsum, coking coal, slag, phosphate and other minerals. |

||||

Main Technical data of CLUM1736 Ultrafine Vertical Roller Mill

| Items | Ultrafine GCC (CaCo3) Powders | |||

|---|---|---|---|---|

| Capacity | T/H | 14.0-19.0 | 12.5-14.5 | 10.0-11.0 |

| Specific Surface Area | cm2/g | 11000±500 | 13500±500 | 15000±500 |

| 325 mesh Residual | % | 0.01 | 0.005 | 0.05 |

| Content <2um | % | 34 | 38 | 46 |

| Average Particle size: D50 | μm | 4.2 | 3.0 | 2.4 |

| Size Distribution :D97 | μm | 28 | 23 | 19 |

| Particle Size Cut Point | μm | 60 | 42 | 36 |

| Mositure | % | below 0.3 | below 0.3 | below 0.3 |

| Power Consumption | KW/Ton | 37~39 | 38~48 | 45~51 |

| Testing Method |

1. Size distribution: To be tested by Malvern3000 Laser Analyser from MALVERN UK company. 2. Specific surface area: Transffered by average particle size, the unit is related area of 1g powder. 3. Average particle size: To be calculated according to particle size distribution. 4. 325 mesh residual: To be marked by percentage, by putting 1000g wet powder samples through 325 mesh sieve. 5. Mositure: Put 5g sample on moisture analyzer, in 6 minutes with temperature 150℃ 6. Application materials: limestone, calcium carbonate, dolomite, talc barite, wollastonite, brucite, calcium hydroxide, gypsum, coking coal, slag, phosphate and other minerals. |

|||

FAQ

Who we are?

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Which models can be selected for processing ultra-fine powder?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829

Inquiry:

Product List